Residences, the cars we drive, the bridges we can cross, the places where we can work, including everyday appliances, we heavily depend on steel. But behind all this hard metal, there is the infrastructure of companies that make sure that steel arrives where it is needed: the steel suppliers.

This article explains in simple terms what steel suppliers do, or rather, what their significance to suppliers is. Moreover, in case you intend to purchase steel, we will present some useful ideas on locating the appropriate provider of steel to conduct your project.

What Do Steel Suppliers Actually Do?

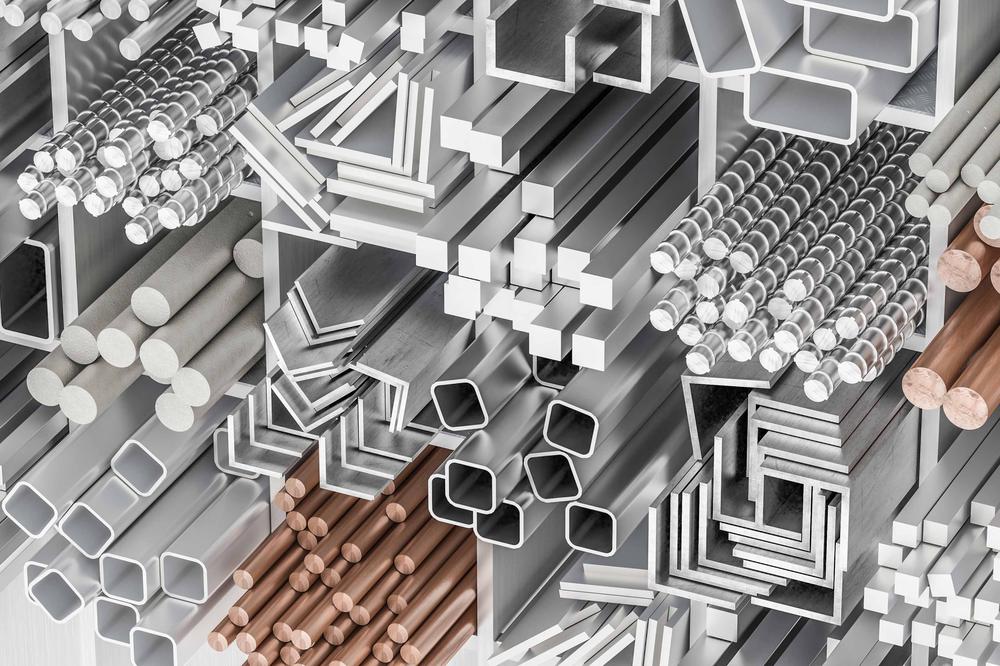

Consider steel suppliers to be the middle between the steel manufacturers and the client who requires steel. They buy steel in bulk quantities in the factories and sell in hoped-down sizes to the builders, manufacturers or anyone who may need it in a particular form, such as sheets, bars, tubes or coils.

It would be a lot slower and more difficult to obtain the correct type of steel at the proper time and in the proper form without steel suppliers.

Why Are Steel Suppliers So Important?

Imagine beginning a construction project of some kind, or a manufacturing job, with no knowledge of when your steel will come. It may be costly to face delays. It is the role of the steel suppliers at this point:

- They maintain stock with steel; therefore, you do not have to wait.

- They provide different options of types of steel that suit your needs.

- They also give professional guidance on the steel that would be suitable for your project.

- They ascertain its quality and safety.

In other words, steel suppliers ensure the smooth progress of your project by removing the pains of finding steel.

Different Types of Steel You May Need:

All steel isn’t all alike. Suppliers usually provide a number of varieties:

- Carbon Steel: The solid, all-purpose metal that is utilised in construction as well as in vehicles.

- Alloy Steel: Enhanced with metals like nickel or chromium to impart added strength.

- Stainless Steel: It does not rust easily and can be used in kitchens, medical equipment and outdoors also.

- Tool Steel: It is extremely hard and resistant, and will make an excellent tool for cutting and reproducing gadgets.

- Structural Steel: It is fabricated specifically to build infrastructure and building frames.

The information about which kind will be appropriate will allow you to understand which supplier is suitable.

Who Uses Steel from Suppliers?

The businesses that steel suppliers cater to are many:

- Building: steel is the infrastructure of buildings and bridges.

- Automotive: Auto parts rely on steel to be safe and sound.

- Manufacturing: It is the role of machines and tools to produce different steel components.

- Energy: Oil, natural gas and renewable energy make use of steel pipes and turbines.

- Shipbuilding: Non-corroding and long-life steel is used in ships and offshore establishments.

Different industry sectors have different suppliers who are knowledgeable about their business needs.

How to Choose the Right Steel Supplier:

Choosing a steel supplier is not only a price issue. In this regard, take into account the following:

- Quality: They must offer standard steel in the industry.

- Variety: There are a variety of steel options that will simplify your life.

- Delivery: Good shipping services that are customer-friendly are very important.

- Customer Support: Customer service with friendly employees who can help you explain your options would be worth a fortune.

- Pricing and Terms: Rates should be competitive, and payment terms or order quantities should be flexible.

- Place: A local provider can minimise the delivery time and expense.

Trends in the Steel Supply Industry:

The steel supply industry is changing:

- A lot of suppliers have become more technologically advanced and provide online ordering and stock tracking.

- Eco-friendly initiatives would translate into more recycled steel and more green practices.

- Others offer custom cutting, processing, which will supply ready-to-use steel.

- Global sourcing runs the risk of having a variety, which impacts time and prices.

Challenges Steel Suppliers Face:

- Costs can be affected by changes in the prices of raw materials.

- Supply chains can be interrupted by global events.

- The safety and environmental regulations continue to grow, thus the need to adapt.

- There is intense competition against suppliers, forcing them to increase their provision of service.

Conclusion:

The steel suppliers contribute significantly to the forward motion of the industries and projects by ensuring the right steel at the right time at the right place. In the search for a supplier, pay attention to the quality of the products, service and reasonable prices to facilitate the process.

A bit of research and asking questions, making comparisons can save you time, money and stress. Steel can be tough, after all, but a supplier should not.

also read: Quality Tyres Worthing Drivers Can Trust – Sussex Tyre Services