Structural Insulated Panels (SIPs) are transforming the construction industry, offering sustainable, efficient, and high-performance solutions for residential and commercial buildings. SIP panel manufacturers are at the forefront of this revolution, providing high-quality materials that enhance energy efficiency, speed up construction, and improve building durability. This article explores the significance of SIP panel manufacturers, the benefits of metal insulated panels, and the importance of controlled environment panels in specialized construction projects.

Understanding the Role of SIP Panel Manufacturers

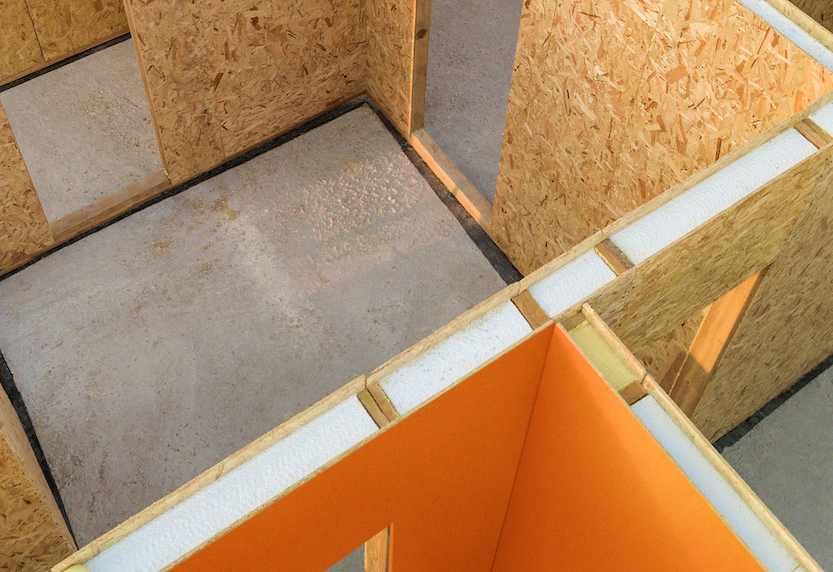

Manufacturers of Structural Insulated Panels (SIP) are integral to contemporary construction, as they are responsible for the design and production of high-performance building materials. These manufacturers ensure that SIPs meet industry standards for thermal performance, structural integrity, and moisture resistance. Unlike traditional construction materials, SIPs consist of an insulating foam core sandwiched between two structural facings, commonly made of oriented strand board (OSB), metal, or other durable materials.

Key Aspects of SIP Panel Manufacturing

- Material Innovation: SIP manufacturers are continually innovating materials to enhance strength, insulation, and fire resistance. Advanced insulation cores, including polyurethane and graphite-infused polystyrene, improve thermal performance while maintaining lightweight properties.

- Precision Engineering: High-tech machinery and automated processes allow manufacturers to cut SIPs with precision, reducing on-site waste and improving installation efficiency. Prefabrication ensures panels arrive at the construction site ready to assemble, minimizing labor costs and time.

- Customization and Versatility: Leading SIP panel manufacturers offer bespoke panel sizes, thicknesses, and coatings for energy-efficient homes and commercial facilities.

The Growing Demand for Metal Insulated Panels

Metal insulated panels are gaining popularity in the construction sector due to their exceptional durability, thermal efficiency, and resistance to weather conditions. Unlike traditional SIPs that use OSB facings, metal insulated panels feature a rigid foam core encased between layers of metal, typically aluminum or steel.

Advantages of Metal Insulated Panels

- Superior Strength and Durability: Metal-insulated panels offer excellent structural integrity, making them ideal for commercial, industrial, and agricultural buildings. Their robust composition ensures they withstand extreme weather, impact, and wear over time.

- Energy Efficiency and Insulation: The insulation core in metal panels enhances energy efficiency by preventing thermal bridging and reducing heat transfer. As a result, buildings are more ecologically friendly and their heating and cooling expenses are reduced.

- Low Maintenance Requirements: Unlike wood-based SIPs, metal-insulated panels resist moisture, mold, and pests. Long-term maintenance expenses are decreased by their easy cleaning and smooth surfaces.

- Fire Resistance: Many metals insulated panels are designed with fire-resistant cores, adding an extra layer of safety in construction. This makes them a preferred choice for warehouses, data centers, and manufacturing plants.

Controlled Environment Panels: A Critical Innovation

In industries that require strict environmental control, controlled environment panels are indispensable. These specialized SIPs are designed to regulate temperature, humidity, and air quality, ensuring optimal conditions for sensitive applications such as laboratories, pharmaceutical production, and food storage.

Why Controlled Environment Panels Are Essential

- Precision Temperature and Humidity Control: Controlled environment panels provide superior insulation, preventing external temperature fluctuations that could affect the stability of sensitive materials.

- Air-Tight Construction for Contamination Prevention: These panels create sealed environments, reducing the risk of contamination from dust, bacteria, or airborne particles. This is critical for cleanrooms, medical facilities, and high-tech manufacturing plants.

- Regulatory Compliance: Many industries, including pharmaceuticals and food processing, must comply with strict environmental regulations. Controlled environment panels help businesses meet these standards by providing consistent climate control.

- Noise Reduction Properties: In research and industrial settings, controlling noise levels is essential. These panels often include soundproofing capabilities, enhancing working conditions in specialized facilities.

Future Trends in SIP Panel Manufacturing

The SIP industry is evolving rapidly, with new trends shaping the future of construction.

- Sustainable and Eco-Friendly Materials: With the rising demand for green buildings, SIP manufacturers are developing panels with recycled materials and bio-based insulation cores.

- Smart SIP Panels: Integrating IoT sensors into SIPs allows real-time monitoring of temperature, humidity, and structural integrity, improving building maintenance and energy efficiency.

- Hybrid Panel Solutions: Some manufacturers are combining SIPs with metal insulated panels or controlled environment panels to create multi-functional building solutions.

- Prefabrication and Modular Construction: Prefabricated SIP panels enable faster and more efficient modular building assembly, reducing construction waste and costs.

Final Thoughts

SIP panel manufacturers are driving the future of construction by providing high-performance, energy-efficient, and customizable building solutions. Whether it’s metal insulated panels for industrial use, standard SIPs for residential projects, or controlled environment panels for specialized industries, these innovations are reshaping how buildings are designed and constructed.

Investing in SIP technology not only enhances building efficiency but also contributes to sustainability, cost savings, and superior performance. As construction continues to evolve, SIP manufacturers will remain at the forefront, offering cutting-edge solutions for the next generation of buildings.

Also read: The Role of Social Media